In the mechanical processing industry, the limitations of traditional processing equipment often act as obstacles to the improvement of production efficiency and processing accuracy. Ordinary saw machines can only complete the cutting process, tapping machines focus on thread processing, and

grinding machines are limited to surface grinding. Single-function equipment not only occupies a large amount of workshop space but also leads to low production efficiency when frequently switching equipment. The high-precision processing of complex parts is even more difficult to achieve. However, the CNC inclined lathe we have launched is an integrated and efficient solution to these problems. It has helped many enterprises break through processing bottlenecks and significantly improve production efficiency.

The CNC inclined lathe, with its advanced CNC system and inclined bed structure design, can perform complex processes such as turning, drilling, boring, and thread processing on various parts like shafts and discs. Compared to the single processing mode of traditional equipment, it can complete multiple processes in one setup, significantly reducing the error of workpiece clamping and improving processing accuracy and production efficiency. The inclined bed design makes chip removal more smooth, and combined with high-precision servo motors and precise ball screws, it can achieve stable and efficient processing for both common metal materials and special alloy materials, and is widely used in automotive manufacturing, aerospace, mold processing, and other fields.

Product features:

Multi-process integration: Complete multiple processing in one setup, reduce errors, and improve efficiency.

High-precision stable processing: The inclined bed structure combined with precision components ensures processing accuracy.

Wide applicability: Suitable for the processing needs of various materials and industries.

Tips:

Regularly check the parameters of the CNC system to ensure stable processing accuracy.

Clean the machine promptly after processing to keep the chip removal channel unobstructed.

Spindle description: The spindle with high precision spindle bearing group and precision assembly and dynamic balance test ensures high precision, low noise and strong rigidity of the spindle.

Tool tower description: Choose the tool tower mode, the tool change speed is fast, the positioning accuracy is high.

Commonly used for hydraulic tool tower and servo tool tower, can also choose power tool tower.

Chuck description: Wedge through hole chuck, fast clamping and loosening the workpiece under hydraulic action, fast clamping speed, high precision.

Transmission description: The screw and nut are processed, ground, assembled and quality control in the constant temperature workshop, which can ensure its high-precision stability. The friction coefficient of the line rail is small, the moving speed is fast, and the precision is high.

Tail seat description: The hydraulic tail seat is processed by manual (or hydraulic) adjustment, manual (or hydraulic) locking, and hydraulic piston jacking the workpiece.

Machine tool lubrication description: RBCLB-3ZK type positive displacement lubrication pump, automatic lubrication, mainly the bed guide rail and the dovetail surface, the lubrication surface between the ball screw and the nut continuous oil supply.

2、Main technical parameters:

Attention:

- When installing a chuck or fixture, please pay attention to the limit speed of the selected chuck or fixture.

- CNC machine tools on the power supply requirements are strict, if the user's power grid fluctuations of more than ±10%, must increase the voltage regulator, otherwise CNC machine tools will not work normally, and even unpredictable results.

- The machine tool does not update the configuration regularly, the specific parameters should be subject to the latest configuration, the specific details will be detailed in the negotiation.

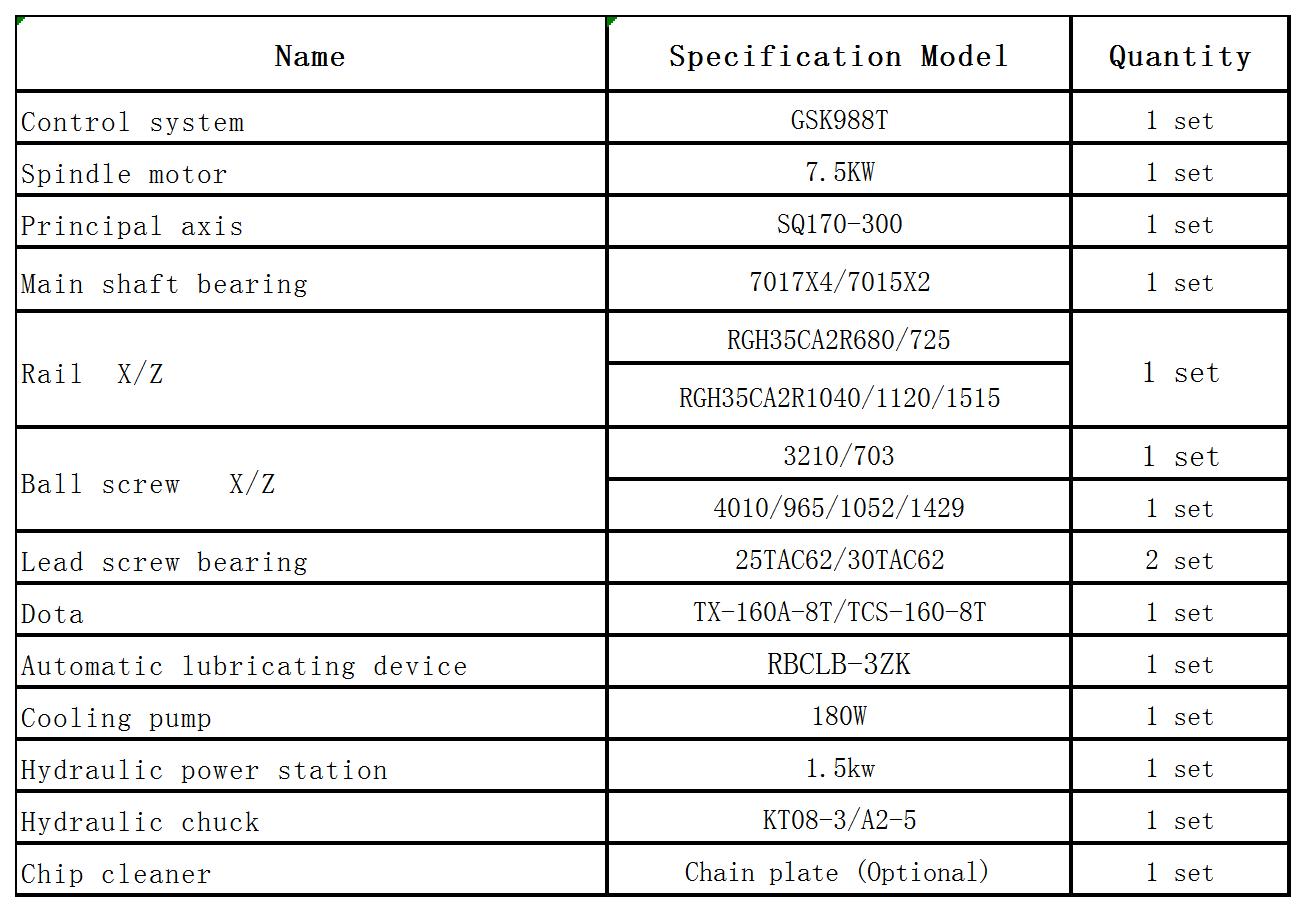

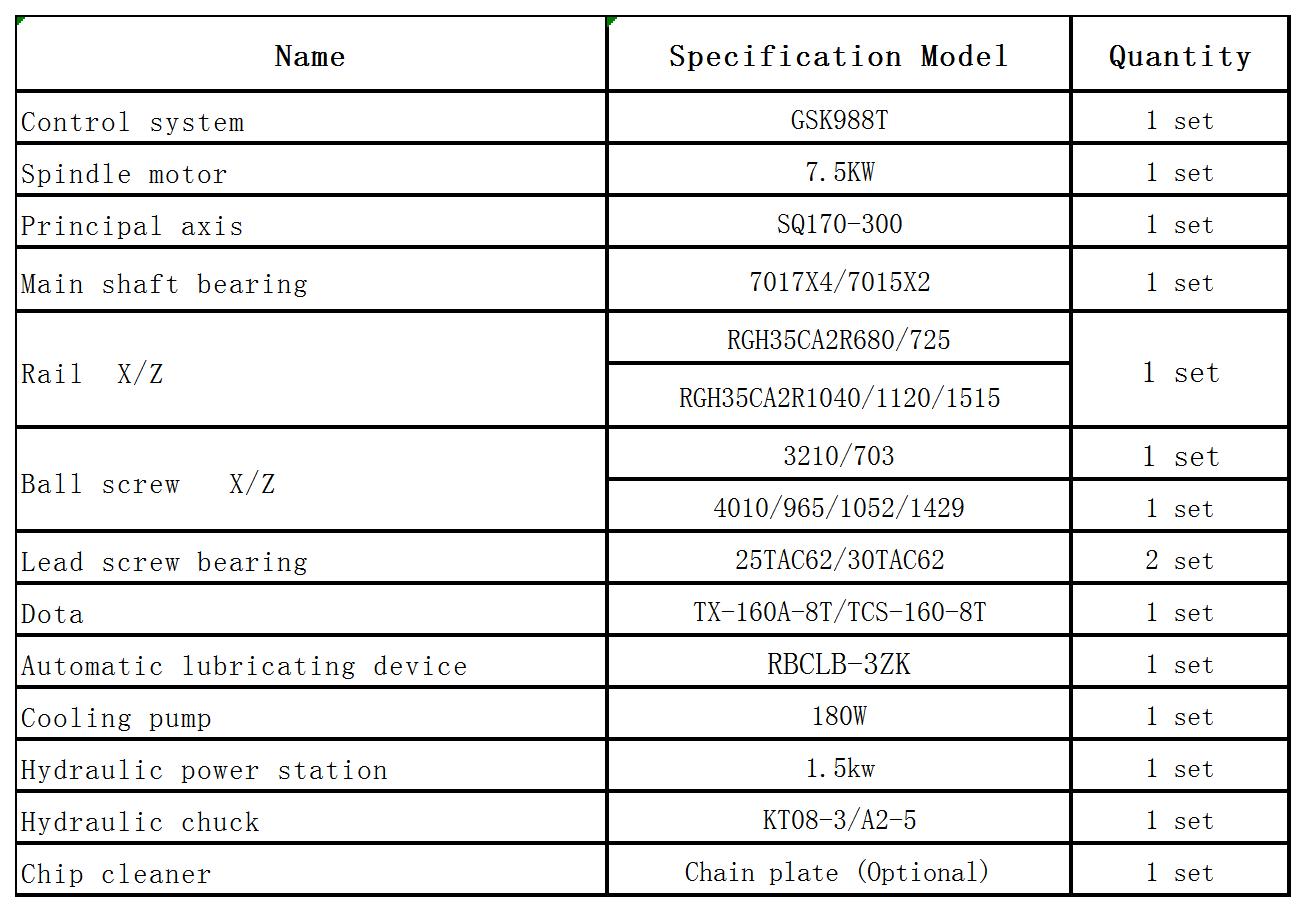

3、Machine configuration list:

4、Machine tool accuracy standards